cruhser liners

Kenco Longer Wearlife Parts | HSI Apron Liners

Tungsten carbide impregnated AR steel apron liners out wear manganese in certain HSI crusher applications; Elimination of premature apron liner wear greatly

Crusher Wear Parts | Weir ESCO

ESCO is a leading developer of heavy-duty wear parts for all major makes and models of cone, jaw and gyratory crushers. ESCO crushing experts work with customers to recommend a variety of high-impact options designed to maximize crusher production. ESCO’s unique designs, tested alloys and superior local service provide specific solutions for

cruhser liners | LT1100 STRAIGHT ADAPTER F870XS16M18

cruhser liners AR Steel Crusher Liners - Crusher Wear Liner Supplies. Ford Steel offers Wearalloy 400, 450, 500, Nickel Chrome Plus Plate and Mangalloy plate up to 4-inches thick for AR steel crusher liners in impact, jaw, cone and other types of crushers. Wearalloy Superclad available for use as cheek plates too.

cruhser liners 1‑1/2 Inch Inch Chrome St

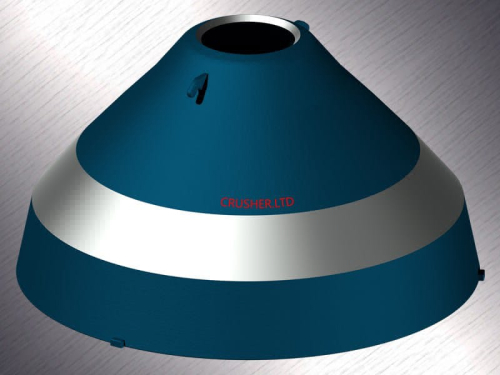

CONE CRUSHER LINER. Key words: Mantle, Bowl Liner, Concave. Permanscess has been providing premium manganese steel and hight chrome crusher liners for decades. our liners have Haoliners Animation League. Haoliners Animation League is a Chinese animation company based in Shanghai and established in 2013.

Crusher Wear Parts - Columbia Steel Casting Co., Inc

Cone crusher wear parts manufactured by Columbia Steel. We manufacture liners for all popular cone crushers, with designs for better production and longer

Jaw Crusher Liner, Swing and Stationary Jaw Plate

The jaw crusher liner is also called the tooth plate, which is an important part of the jaw crusher. A set of jaws is usually composed of movable jaws and fixed jaws. According to different

cruhser liners RING (TWO PIECE) S&H6000

06/27 · When to change crusher liners. It is an important thing when to change crusher liner, so as to avoid damage to the liner seating surfaces of the crusher bowl, concave and mantle must be replaced before they are worn through. In some conditions with good quality wear parts , approximately 50% of the liner weight is consumed when

cruhser liners | crusher spare wearing plate list

Manufacturer of Cone Crusher Liners & parts — improve performance through optimisation. In order to help your site maximise its operational performance, we design Cone Crusher Liners and wear parts that are tailored specifically with your needs and goals in mind. What we offer. Productivity enhancements for your cone material crushers.

How Long Should Rock Crushing Equipment Liners Last? - Mellott Company

Liners might last for years when used to crush soft rock materials, such as talc, onyx, alabaster, or soft limestone. Harder, abrasive minerals, like granite, however, may wear out liners within a month. Other factors, such as continuity of run time, may come into play as well, but the primary determinant toward the life of liners is the

AR Steel Crusher Liners - Ford Steel

Our company provides crusher wear liner supplies to a wide range of industries including: Sand & Gravel; Cement; Construction. Contact Our Team.

Selecting crushing chambers for cone crusher - Outotec

Illustrative figure of HP cone crusher liners. To ensure the suitability of the liner profile for its application, it is important that

+86-21-63353309

+86-21-63353309

Leave a Comment